Manufacturing. Made Simple.

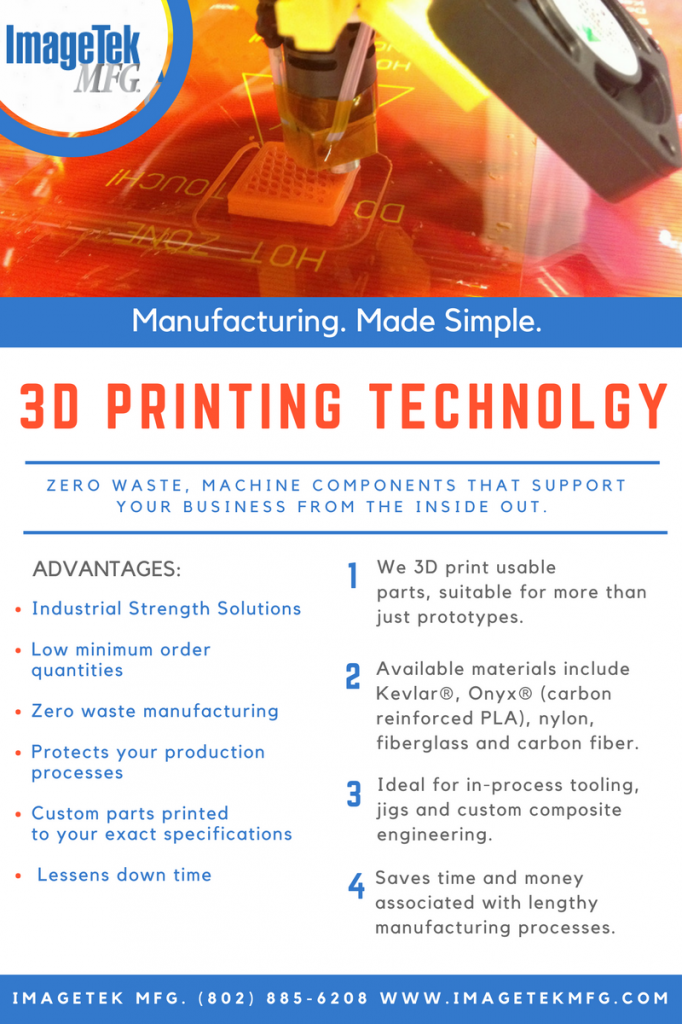

ImageTek Mfg. has expanded their capabilities to include 3D printing of usable, in-process tooling and composite engineering components. This cutting edge print technology offers more than just standard 3D prototype solutions, parts are printed with Kevlar®, Onyx® (carbon reinforced PLA), fiberglass, carbon fiber and nylon, delivering finished products with rugged durability. 3D printing is a natural fit for ImageTek’s existing customer base, allowing engineering professionals, manufacturing facilitators and inventors the opportunity to order usable, low volume parts, manufactured to their exact specifications. Better yet, 3D printing offers a zero-waste, eco-friendly means of production that supports lean manufacturing initiatives.

Benefits of 3D Printing Also Include:

- Stronger-than-aluminum composite parts and jigs

- Lessens downtime associated with broken equipment and replacement shipments

- Low minimum order quantities and quick delivery

About ImageTek Mfg.

Since 1994, ImageTek Mfg. has been a valued partner to industry leaders in the Machine Tool, Electro Mechanical, Medical Equipment Manufacture and Renewable Energy fields. ImageTek Mfg. provides printed circuit board (PCB) assemblies and turn-key electronics manufacturing services (EMS or box build), as well as automated print technologies, specialty media and printed labels for customers across the globe. Located in the heart of the Precision Valley in Springfield Vermont – ImageTek Mfg. is dedicated to extending your capabilities by offering quality, cost effective and responsive services.